Uncategorized

The Role of Testing and Commissioning in Meeting Lifting Equipment Regulations

When lifting equipment is involved in your business, you understand how essential safety is. Lifting operations are a real danger, whether you work in construction, shipyards or even in pharmaceuticals. Singapore has stringent safety and health laws in the workplace that make such regulations on lifting equipment an unavoidable issue. That’s where testing and commissioning come in. These steps aren’t just routine—they help you comply with the law and ensure every lift happens safely. At Jenmon, we ensure that your equipment functions as it should at the start. It is simply a matter of safety, reliability, and peace of mind.

Understanding Lifting Equipment Regulations in Singapore

Lifting equipment consists of cranes, hoists, shackles, and even lifting belts- anything used to raise or lower loads. The regulations used in Singapore are according to the Workplace Safety and Health (WSH) Act and the Codes of Practice by the MOM. These acts have clear guidelines on your duty to ensure that lifts remain safe. Your gear should be inspected and certified by a good individual or a legal examiner regularly. You have the responsibility as an employer to ensure that you organise inspections, carry out proper certification and make everything orderly. None of these rules is optional, especially when handling lifting gear.

What is Testing and Commissioning in the Context of Lifting Equipment?

Testing checks if your crane or lifting machine can safely carry the intended load. Commissioning is what follows—calibrating, adjusting, and making sure the system works in real conditions. At Jenmon, we do this for cranes, hoists, and other complex lifting machines. These steps help confirm the safe working load, proper functionality, and adequate strength. We ensure that everything runs at maximum capacity before your team uses the equipment. Missing these steps endangers your operation and people. That’s why testing and commissioning come first, every time.

Why Thorough Examination Is Required Before Every Lift

Before every major lift, your equipment needs a thorough examination. This isn’t just a box to tick—it’s required at regular intervals under the law. An authorised examiner must inspect, examine, and certify the equipment. Such defects will be detected early before accidents occur. Other gears under modification, repairs, or reassembly also require new testing. At Jenmon, we help you stay ahead of this. Regular checks catch problems before they become dangerous. It’s a smart way to protect your people and your project.

Maintenance and Inspection: Your Ongoing Responsibility

Lifting equipment should also be maintained in the best condition by continually repairing and inspecting it. As an operator or employer, you have to make things secure and work on the correct terms. You should observe inspection periods, maintain certification, and carry out any indications of wear or defects. If you don’t, you’re breaching your obligation—and someone could get injured. At Jenmon, we stress continuous assessment because it’s reasonably practicable and helps avoid unexpected issues. Mark your gear, track the condition, and fix defects fast.

Managing the Risks: Compliance Isn’t Optional

Ignoring lifting equipment regulations doesn’t just risk injury—it could shut your project down. Non-compliance leads to broken machines, legal penalties, and serious delays. Compliance helps ensure stability, safety, and smooth operation. You need a risk management system that covers accident investigation, certification, and safe working practices. Maintain good records- load charts, inspection certificates, operator records and examiner reports. These are not just papers, but evidence that you are doing your bit in keeping the workplace safe. At Jenmon, we help you stay ahead—before trouble starts.

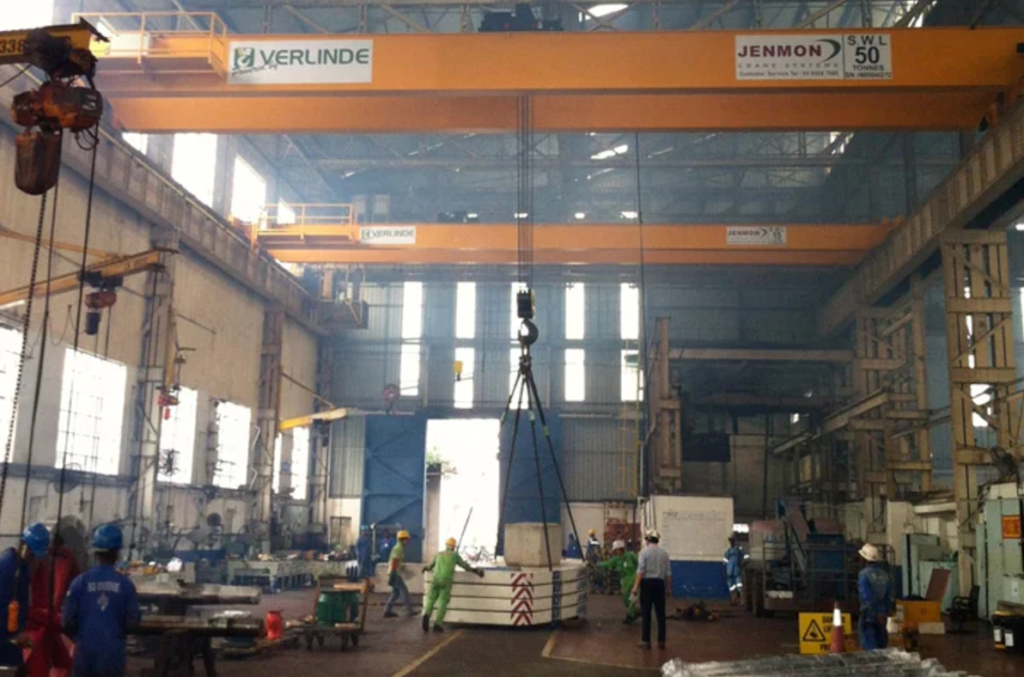

Jenmon’s Testing and Commissioning Services

At Jenmon, we test and commission cranes of all sizes, ranging from under 1 tonne to over 100 tonnes. We make sure every test complies with SS497 and international standards. Our load tests and visual inspections confirm that your equipment’s structure, mechanical systems, and electrical components work properly and safely.

Here’s how we make your life easier:

- Automated tracking of your crane’s testing dates

- Automated tracking of your maintenance schedule

- On-site or in-house testing for equipment and accessories

- Load Test planning for safe, smooth operations

- Provision of test loads, lifting gears, and devices

- MOM Certificate issued in line with local regulations

Final Thoughts: Select the Right Partner for Safe Lifting

Testing, commissioning, and careful investigation are the most important components to keep in line with regulations concerning the use of lifting equipment. These are not only legalities that are being checked off; they ensure your people’s safety and the project’s smooth flow. At Jenmon, we are not only providing you with services but also taking responsibility together. Starting somewhere new, or simply continuing to manage, we have the tools, experience and knowledge to assist you. How about we transform your lifting work to be safer, smarter and 100% compliant?

Reach out to Jenmon today—your reliable partner in safe lifting.