Jenmon | Blogs

Jib Cranes: When Are They the Most Practical Lifting Solution for Confined Workspaces?

Lifting tasks can become challenging when work needs to be carried out in confined spaces, such as areas with narrow aisles, fixed machinery, or low ceilings. In such situations, you do not require a large crane system. You require something small, flexible, and easy to manipulate. That is where jib cranes come in.

A jib crane can help make your everyday work easier and safer in a limited space, such as a workshop, warehouse, or workstation. We will discuss what jib cranes are and under what circumstances they are most suitable in your space.

What Are Jib Cranes?

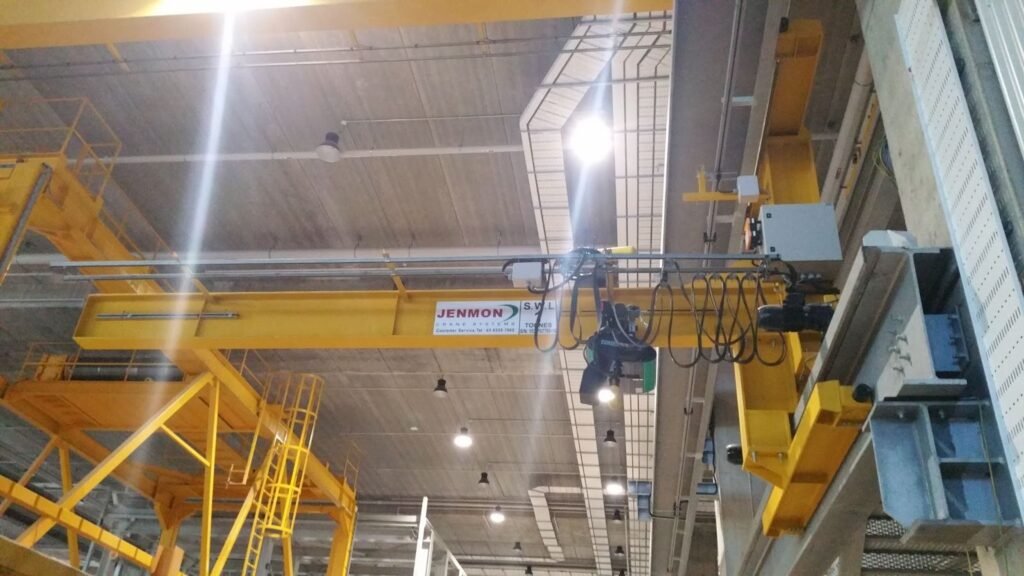

A jib crane is a cost-effective lifting device where the horizontal arm, known as a jib, moves loads. A hoist and trolley are supported by the jib and assist in efficiently transporting and placing materials. The jib can be rotated to put the loads on a smooth motion rather than dragging them on the floor.

Jib cranes can be frequently seen in any material handling section, around machines, or at each workstation. They are good for overhead lifting activities that require control and speed. You can apply them to lift items, transport equipment or place equipment without any strain.

Jib cranes are concentrated on a single work area, unlike larger crane systems. Such a focus makes them cost-effective, ergonomic and simple to use.

When Are They the Most Practical Lifting Solution for Confined Workspaces?

Limited Floor Space and Tight Workstations

When floor space feels limited, every move counts. You can’t afford wide travel paths or bulky equipment. A jib crane lets you lift and rotate loads within a small radius.

A jib crane can be attached to a machine or a work station. The lifting is done by the crane, and you are in control. This setup improves productivity and keeps the area clear. You also reduce manual handling, which protects your team from injury.

In a busy warehouse or production area, that kind of control makes a real difference.

When Wall or Pillar Support Is Available

You have the upper hand in case your building has strong walls or columns. A wall jib crane or a wall-mounted jib crane is fixed to a reinforced wall or structural beam, allowing lifting operations without occupying floor space. This alternative conserves floor space and makes walkways free.

You can also choose a pillar jib when wall support isn’t available. The pillar anchors to the floor and supports the jib without needing extra brackets. Both options offer stable lifting when the structure is reinforced properly.

These designs are suitable for workshops and facilities in Singapore, where space is often at a premium.

When You Need Flexible Movement and Rotation

Some lifting jobs need more than straight-line movement. You may need to rotate, swivel, or reach around obstacles to navigate. An articulating jib crane gives you that freedom.

This type of jib utilises joints that allow you to move loads around machines and corners. You can also choose slewing designs that rotate up to 360°. That range helps you position loads exactly where you want them.

When you pair the jib with a smooth trolley and hoist, you gain full control over every lift.

When Load Capacity and Service Classification Matter

You must always match the crane to the job. All jib cranes have a load capacity and service rating. These ratings indicate both the maximum load capacity and the frequency of operation the crane is designed to handle safely.

When you have to move light loads throughout the day, you should have a strong crane that can withstand a high frequency of use. If you lift heavier parts now and then, you need strength and stability. Good crane design keeps the system safe, balanced, and reliable.

You should never guess here. The right configuration protects your people and your machinery.

When You Want a Cost-Effective and Simple Crane System

Not every site needs a large overhead system. Sometimes, simple works best. A freestanding jib crane gives you lifting power without complex rails or monorail systems.

Freestanding designs use a cantilever arm and strong anchor bolts. They stand on their own and suit flexible layouts. You may put them where you need them most.

These cranes are a cost-efficient alternative to small to mid-sized lifting assignments. They enhance workflow, reduce the load, and improve efficiency at low costs.

Conclusion

You should choose jib cranes when space is tight, lifting tasks are repeated daily, and control is crucial. They fit well in confined workspaces, support safe material handling, and improve how you move loads.

Whether you need wall-mounted support, pillar strength, or full rotation, jib cranes give you options. They help you lift smarter, not harder.

At Jenmon, we design and supply jib cranes that match your workspace, load needs, and workflow goals. Need a solution that fits into your space and works effectively with your team? Get in touch with us. Our goal is to provide reliable lifting solutions that integrate seamlessly into your operations.