Jenmon | Blogs

Enhancing Safety with Self Centering Devices: The Future of Lifting Equipment in Singapore

Singapore’s construction and marine industries operate with heavy loads on a daily basis, which makes safety a prime factor in every lifting task. Lifting equipment can be hazardous if not managed correctly. In fact, most workplace accidents occur due to load swinging and improper load centering, emphasising the need for strict safety measures.

This is precisely why self centering devices have made such an impact. To eliminate potential accidents even before they happen, these cutting-edge tools come into play, to ensure every lift is easier and safer.

The Role of Self Centering Devices in Modern Lifting Equipment

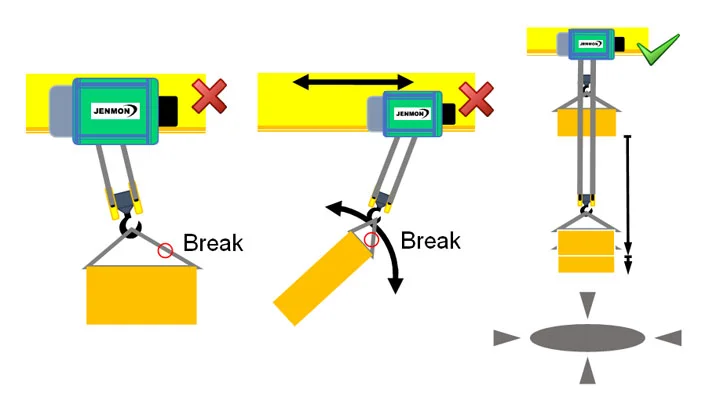

Self-centering devices work like smart assistants for lifting equipment. They automatically adjust the position of hooks and loads to keep everything balanced. Think of them as invisible hands that guide heavy items into the perfect spot. These devices use innovative engineering to detect when something’s off-centre. They then make quick adjustments to keep loads stable and prevent dangerous swinging. Workers can now move heavy items more confidently, knowing their equipment will help maintain control and balance throughout the lift.

Types of Lifting Equipment That Benefit from Self Centering Devices

1. Gantry and Overhead cranes

Gantry and overhead cranes operate in manufacturing, warehousing, and construction settings, needing precise positioning of loads. The self centering device is able to align the loads accurately, reducing the risk of imbalance and minimising unnecessary stress on the crane structure. This makes the process more efficient as it reduces the need for manual adjustments, thereby also facilitating safer, smoother, and faster lifting operations.

2. Hoists, Slings, and Shackles

Safety and efficiency are paramount for every lifting operation, which is why the right tools are essential.

- Hoists are used to lift and lower heavy loads, and self-centering devices can aid in keeping loads stable to avoid swinging.

- Slings secure objects for stabilisation, while self-centering technology evenly distributes weight to minimise wear and tear.

- With the help of shackles, various lifting components can be connected to each other, with the self-centering devices improving alignment and securing the connection even more to reduce the strain on the lifting system.

3. Monorail Hoists & Jib Cranes

Monorail hoists and jib cranes operate in confined spaces in workshops, factories, and shipyards. Such systems operate with precise movement to lift thin or heavy loads. Self-centering technology removes the risk of misalignment, enabling lifting that is more controlled and precise, while minimising the chances of side-loading which can damage the equipment.

4. Lifting Beams and Spreaders

When large or unwieldy shaped loads need balancing, it’s done with the use of lifting beams and spreaders. These devices also distribute the weight evenly across the beam, which prevents both the equipment and the load from taking on too much stress. It is useful particularly in logistics, shipping, and sectors that deal with bulk products, as well as in heavy industry — when you have to lift heavy cargo or machinery, it needs to be done safely and efficiently.

5. Automated Lifting Systems

Automated lifting systems are increasingly used throughout material handling in the modern warehouse and industrial facility. Such self-centering devices enhance reliability and accuracy, while guaranteeing that each lift will be efficient, safe, and suited for high-volume applications.

The integration of self-centering technology within these types of lifting equipment can provide businesses with significant benefits, including enhanced safety, decreased downtime, and improved operational efficiency.

Ensuring Compliance: Inspection and Certification for Lifting Equipment

The lifting operation business in Singapore is taken very seriously, and the Ministry of Manpower (MOM) has strict regulations that businesses have to abide by. Cranes and lifting equipment must all be registered with MOM prior to use.

Companies must obtain type approval for any new lifting equipment before it is used. Regular inspections by MOM-appointed Accredited Engineers (AEs) ensure continued safe operations. Although every piece of equipment needs to undergo an in-depth inspection once a year, equipment used more regularly or in more extreme environments may require such inspections more regularly.

To facilitate this process, MOM offers online services to simplify registration, renewal and inspection appointment making. This platform enables companies to track the status of their equipment, update files, and schedule inspections — all in a more timely manner. By adherence to these regulations, businesses can lead to safer work environments and comply with MOM’s safety standards.

The Future of Lifting Equipment: Safer, More Reliable, and Efficient Solutions

The lifting industry keeps getting smarter and safer. Engineers develop new ways to make equipment more reliable. These advances help workers do their jobs better. At Jenmon, we pride ourselves on staying ahead of these developments. Our self-centering devices represent our efforts in advancing safety technology.

We’ve designed our devices to make operations seamless. They automatically adjust the hook’s position to keep loads stable. This smart design prevents dangerous load swings and protects both equipment and workers. Our customers enjoy many benefits:

- Simple, straightforward operation

- Enhanced workplace safety

- Faster performance and better efficiency

- Less stress on hooks and equipment

- No more load dragging

- Fewer accidents from collisions

- Longer equipment life

- Reduced breakdown rates

- Better protection for operators

Conclusion: Elevating Workplace Safety with Self Centering Devices

Self-centering devices have transformed lifting operations in Singapore. They make every lift safer and more efficient. Smart businesses now choose equipment with these safety features built in. Regular maintenance and quality equipment from trusted suppliers keeps operations running smoothly. Check out Jenmon’s complete range of lifting solutions at our website to learn how we can help improve your lifting operations.