Jenmon | Blogs

Key Features to Look for in an Overhead Electric Hoist for Maximum Efficiency

If your business involves moving around heavy goods, investing in an overhead electric hoist could be the most beneficial decision for your business. These tools make lifting heavy materials easier, time-efficient, and cut the labor costs down to size. But choosing the wrong hoist? That could lead to accidents, downtime, and expensive maintenance that no business is ready to deal with.

For this reason, it’s very important to settle for the right hoist. In this blog, we’ll guide you through the key features that you must look for, so you can pick the good, working hoist that will fit your application.

Understanding Overhead Electric Hoists

Overhead electric hoist is an electric motor-powered lifting device used to lift heavy loads vertically. Since the hoists are installed overhead, they leave floor space free and hence make operations more efficient.

Two types of electric hoists:

- Wire rope hoists, which are more suitable for the heavier load at longer lifting distances.

- Chain hoists, which are best suited for lighter loads and very precise positioning.

Hoists come into play in countless different applications across numerous different industries: factories transporting materials down manufacturing lines, building sites lifting bulky supplies, warehouses shelving inventories, and even LTA projects dealing with large infrastructure components. If lifting is a regular part of your operations, an electric hoist is a must-have tool for efficiency and safety.

Load Capacity and Lifting Mechanism

Selecting a hoist with the appropriate lifting capacity isn’t merely a matter of efficiency but it’s also a matter of safety. Overloading a hoist can damage equipment and put workers at risk.

- Wire rope hoists have a capacity to handle load weights from 1 ton to 100 tons.

- Chain hoists are more suitable for lighter work, generally between 1/8 and 5 tons.

- The height of the lift is an important consideration, as some applications might just require a few feet of lift, while others require heights up to or beyond 100 feet.

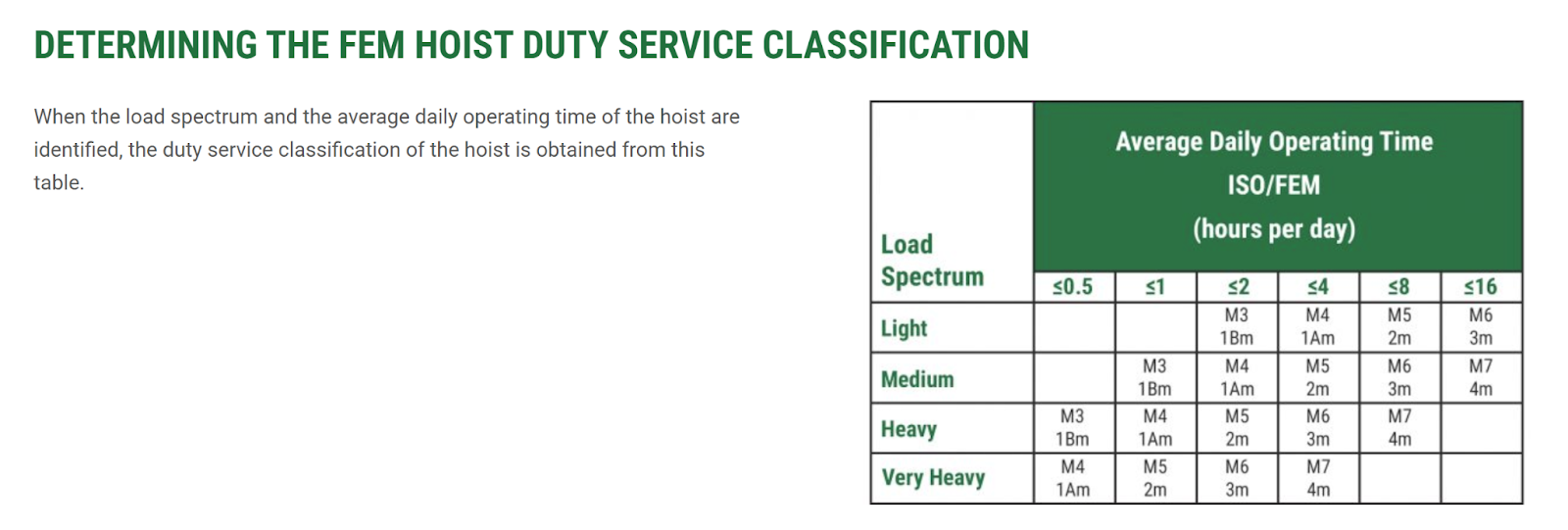

- Duty cycles show how frequently a hoist can be safely used. Light-duty hoists are best used for infrequent use, and heavy-duty types are intended to run continuously. Using these specs to match your requirements provides best performance and life.

Hoist Motor and Power Supply

The motor is the central part of your hoist, controlling its lifting speed and capacity. The higher power motor enables quicker and more heavy-duty lifting, leading to increased productivity.

The majority of electric hoists operate on universal electrical power and are simple to install. Nevertheless, in environments where sparks pose a risk (such as oil and gas industries), the explosion proof hoists constitute a safer solution.

New hoists also feature variable speed controls for accurate lifting and positioning. Thermal protection motors prevent overheating, and electronic regulation systems minimise component stress, thereby increasing the lifespan of the machine. If your hoist works in hot conditions, integrated cooling systems are a good feature to possess.

Safety Features and Compliance

Safety should be the first consideration when selecting a hoist. The best hoists include integrated safety features to safeguard workers and equipment:

- Overload protection – Automatically halts the hoist if it senses too much weight.

- Emergency stop buttons – Enable workers to instantly stop the hoist in case something fails.

- Limit switches – Prevent over-hoisting, which can harm equipment or result in loads falling.

- Brake systems – Retain loads in place even in a power outage.

These attributes allow companies to comply with OSHA regulations and industry safety procedures, avoiding hazards and accidents at a huge cost. Inspections and servicing every so often maintain your hoist in prime condition, and training operators allow staff to detect signs of problems like unusual noises or decreased functionality.

Hoist Suspension and Mounting Options

How you install your hoist will depend on your work space and lifting requirements. Various configurations provide a range of flexibility:

- Stationary hoists – Installed permanently for dedicated lifting duties.

- Trolley-mounted hoists – Travel on I-beams or tracks and give flexibility across a work area.

- Gantry-mounted hoists – Mobile units that do not need fixed overhead installations.

Your mounting selection determines installation expenses and workspace utilisation. Beam mounts work well with strongly supported buildings, while runway systems enable mobility over large spaces. If future business expansion is anticipated, long-term planning saves retrofits costs.

Maintenance and Lifespan Considerations

Similar to any machinery, an electric hoist should be serviced from time to time to work effectively and last long.

- Monthly maintenance – Lubricate and clean chains or cables to avoid wear.

- Weekly maintenance – Check brakes to ensure smooth functioning.

- Visual checks – Examine deformed hooks (indication of overloading) and inspect drum grooves for signs of wear.

- Track maintenance – Maintain wheels and rails free from dirt for frictionless trolley travel.

More stringent environments, such as those with high humidity or corrosive products, call for more regular maintenance. Operations of high-duty cycle also necessitate special care. Adherence to a manufacturer-prescribed schedule of maintenance will keep your hoist in its best condition for 10+ years or more.

Jenmon: Your Lifting Partner of Choice

Selecting the ideal hoist matters—but having a reliable supplier means everything. Enter Jenmon.

We don’t merely sell lifting gear—we deliver complete lifting solutions. From planning and installation through testing and servicing, our specialists are with you every step of the way. And with 24/7 service support, we guarantee that your operations never have to go through unnecessary downtime.

Being the only authorised agent of Verlinde in Singapore, we provide top-notch hoist components as well as produce our own cranes. Our lifting solutions are utilised in various industries to assist companies in increasing efficiency and safety.

With safety as our priority, you can be assured that your investment is secure. At Jenmon, we listen to your unique requirements and recommend the best hoist for your business.

Conclusion

Choosing the right overhead electric hoist is more than just about lifting – it has to do with ensuring that you will have safe operations, efficiency in work, and cost-effective measures in place. By putting together a checklist of basics such as load capacity, motor power, safety features, mounting style, and maintenance planning, you will be able to decide on a hoist according to your requirements. At Jenmon, you are not just purchasing equipment, you are getting a partner who will support you throughout the process.

Need help finding the perfect hoist? Get in touch with Jenmon today!