Jenmon | Blogs

What Are Webbing Slings Used for in Lifting Equipment?

Industries now rely on lifting equipment to perform many tasks. If you are working in construction or at a factory, you need to depend on tools to take care of heavy items without any risks. More than other lifting tools, webbing slings are the most common. These types of slings handle many different lifting tasks and help ensure all your material handling and lifting jobs run smoothly and efficiently.

What Are Webbing Slings?

A webbing sling is a strong lifting device made from polyester fibres braided into a sling. These synthetic materials create incredibly strong straps that can handle substantial loads. The polyester webbing forms either a flat belt design or an endless loop configuration. This woven polyester construction delivers exceptional strength and durability, making each fibre work together to support your heaviest lifting challenges.

Main Applications of Webbing Slings in Lifting Equipment

You’ll find webbing slings handling diverse lifting tasks across various industries every day. To move steel beams, construction teams depend on cranes, and logistics firms use them to handle their goods. Industries use engineering in various ways, such as installing large machines, working offshore, and supervising warehouses. No matter if you need to handle heavy items or only delicate ones, these lifting pieces of equipment can be adjusted for your needs.

Understanding Different Sling Types

When selecting lifting equipment, you’ll encounter several sling varieties, each designed for specific applications. Web slings showcase a flat, ribbon-like design that spreads loads evenly across contact surfaces, making them perfect for protecting delicate finishes. Round slings feature tubular construction with endless loops, offering exceptional flexibility for navigating around irregular shapes and tight corners.

Compared to rigid chain slings and wire rope alternatives, webbing slings deliver superior adaptability whilst remaining significantly lighter. Chain slings are excellent for hot temperature applications and are not very sensitive to handling materials. Wire rope slings are strongly contrasting in favour of strength, but require inspection and lubrication to avoid fraying and corrosion.

The option you choose between these would depend on your particular lifting needs, the requirements of your safe working load, and the flexibility that each task may require. Round slings are also particularly resistant to damage when intact, whilst web slings offer better load distribution for fragile cargo.

Key Features and Benefits of Using Webbing Slings

Webbing slings deliver exceptional performance through these key advantages:

- Remarkable flexibility – You get easy manoeuvrability around awkward loads whilst maintaining lightweight handling

- UV-resistant construction – Your slings withstand harsh outdoor conditions without degrading over time

- Outstanding strength and durability – These reliable tools perform consistently in demanding industrial environments

- Chemical resistance – They protect against corrosive substances better than many alternative lifting solutions

- Sharp edge protection – The woven design resists cutting and damage from rough surfaces

- Gentle on surfaces – Perfect for polished surfaces and sensitive loads requiring careful handling

- Safety and reliability – This combination ensures your safe working operations meet every standard and directive requirement

Safety Standards and Load Limits

Working Load Limit (WLL) determines the maximum weight your sling can safely handle during normal operations. Every sling must conform to safety standards that govern lifting equipment. Understanding your safe working load and working load limits prevents accidents and ensures compliance. Since they are vital to every safety standard, it is important to check and follow the working load regulations.

Choosing the Right Webbing Sling for Your Needs

Selecting the right sling for your specific lifting requirements involves several key considerations. You need to assess capacity, size, and type (endless or loop configurations) for your application. Consider length requirements, potential chemical exposure, and how load distribution affects performance. This range of applications demands careful evaluation to ensure your range of lifting operations achieves correct lifting results every time.

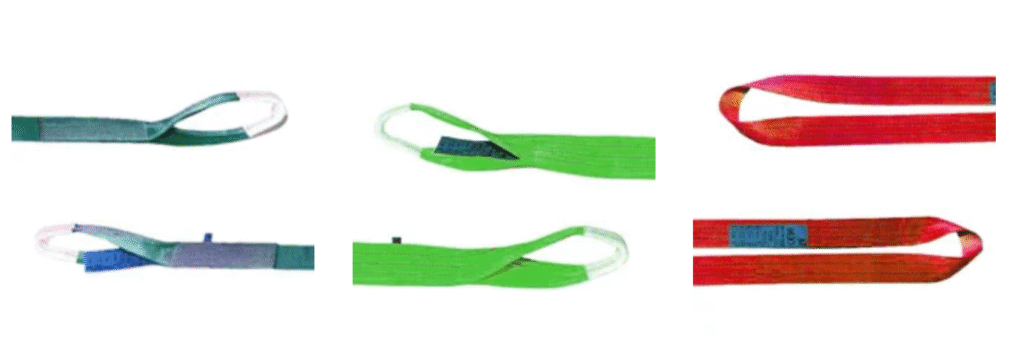

Jenmon’s Webbing Slings

We at Jenmon are fully committed to ensuring that every product meets high standards. Our reputation as a reliable manufacturer allows us to provide webbing slings that only meet the best quality standards. Our range includes:

- Single Thickness Slings for lighter applications

- Double Thickness options for enhanced durability

- Single Thickness Endless configurations for versatile use

- Double Thickness with Steel Fittings for heavy-duty applications.

Each reliable product reflects our dedication to excellence.

Conclusion

Webbing slings represent essential lifting equipment that combines safety, versatility, and reliability in one package. These durable tools handle countless applications whilst maintaining the high-quality performance your operations demand. When you need safe, durable, and high-quality slings for your lifting requirements, Jenmon delivers the reliable solutions you can trust.

Need help with your lifting requirements? Reach out to Jenmon today.