Jenmon | Blogs

Belt Hoists: What Most Buyers Overlook and How It Impacts Your Lifting System

You might think all lifting hoists work the same way, but belt hoists offer something different that many buyers miss. These specialised lifting systems use belts instead of chains to move heavy loads. This makes them perfect for clean environments where traditional electric chain hoists might contaminate your workspace.

What most individuals fail to understand is that selecting a hoist that is not up to standard may cost them thousands of dollars in repair and loss of productivity. The lifting equipment you purchase must suit your application and not necessarily your budget.

What Is a Belt Hoist and How Does It Work?

Belt hoists raise and lower loads by using a continuous loop of belt rather than chains. The belt runs over pulleys connected to an electric or manual drive system. When you activate the hoist, the belt moves through the pulley system to raise your load smoothly. Electric versions give you precise control through pendant controls, while manual options require physical operation.

These hoists are best in clean environments as they do not litter the oil or grease chain systems. The belt system is quiet and offers a smooth operation compared to the conventional electric hoists. Depending on the model that you select, you will be able to lift loads that range between 500kg and 5,000kg.

What to Look for in a High-Quality Lifting Hoist

When selecting high-quality lifting equipment, you need to focus on several key features:

- Brake systems that engage automatically when the power stops

- Manual or electric travel options matching your operational needs

- Pendant control systems for precise load positioning

- Spreader beams for distributing weight across wide loads

- Lug mounting capabilities for secure installation

- Pulley systems are designed for your lifting range and environment

Your hoist must suit your specific application and lifting range requirements. Indoor operations need different specifications than outdoor use, where weather resistance becomes crucial. Low headroom situations require compact designs that still deliver full lifting capacity.

How to Choose the Right Hoist for Your Needs

Identify your maximum lifting capacity needs first, taking into consideration safety margins for unforeseen loads. Measure your lifting height carefully, considering both minimum and maximum positions your loads need to reach. Your workplace environment determines whether you need standard or resistant materials like stainless steel construction.

Consult with trustworthy manufacturers or suppliers aware of your specific requirements. They can provide assistance with your operational needs and budget constraints. Don’t sacrifice durability in order to save money up front. Excellent hoists are available in a range of configurations to suit your specific lifting equipment needs. Seek out suppliers who offer comprehensive support and maintenance services.

How the Wrong Hoist Can Hurt Your Lifting System

Selecting inappropriately matched hoists reduces productivity at work and poses serious safety hazards. You risk equipment failure and possible injuries when your load capacity isn’t in line with your actual needs. Vibrations caused by improper mounting systems damage the supporting beam structures and the hoist.

Improperly integrated trolley systems lead to handling issues. When incorrectly loaded, steel beams can crack and fail catastrophically. Your work environment suffers when maintenance requirements exceed your capabilities. Electric hoist systems need regular servicing that some buyers overlook during selection. Poor quality lifting hoists break down frequently, disrupting your operations and costing more long term.

What Buyers Often Overlook When Choosing a Hoist

Many buyers focus only on lifting capacity whilst ignoring crucial operational features like speed control and brake responsiveness. You might not consider whether manual or electric operation suits your daily workflow better. The range of available accessories often gets overlooked, limiting your system’s versatility later.

Resistant materials like stainless steel cost more initially but save money in harsh warehouse environments. Load chain specifications matter more than most people realise, especially for frequent use applications. Proper control systems ensure operator safety and precise load positioning that cheaper alternatives can’t match. Don’t ignore the total cost of ownership, including maintenance and replacement parts availability over time.

Jenmon Belt Hoists

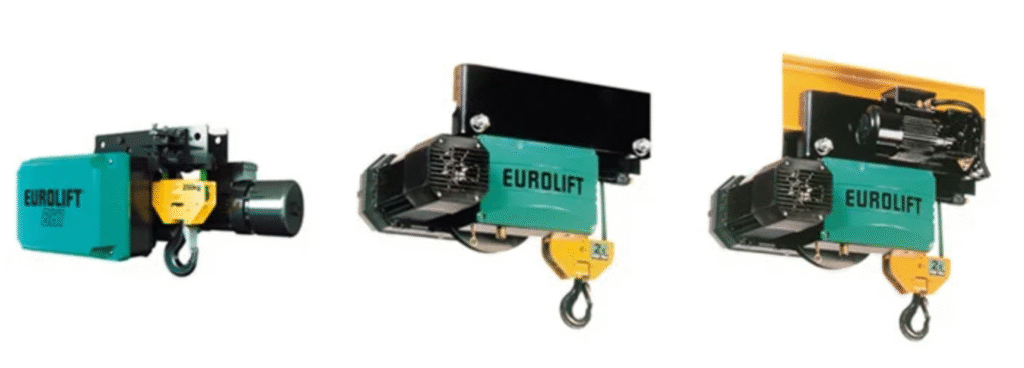

The EUROLIFT BH Electric Belt Hoist delivers exceptional hoisting power whilst maintaining the highest cleanliness standards your facility demands. This robust hoist complies with strict EC European standards, providing reliable lifting performance specifically designed for the Food, Pharmaceutical and Chemical Industries. You get professional-grade lifting power without compromising your sterile work environment.

Here are our belt hoists:

- EUROLIFT BH – Electric Belt Hoists for loads of 500 to 5,000 kg

- EUROLIFT BH, Stainless Steel Version – Electric Belt Hoists for loads up to 2,000 kg

- EUROLIFT BH, Fixed Suspension Version – Electric Belt Hoists for loads of 500 to 5,000 kg

- EUROLIFT BH, Low Headroom Version – Electric Belt Hoists for loads of 500 to 5,000 kg

If you want to know more about our products, click here to request for technical sheet.

Conclusion

Smart buyers avoid costly mistakes by understanding these often-overlooked aspects of hoist selection. Your lifting hoists must match your operational needs, not just your initial budget constraints. Electric chain hoist systems require careful consideration of your workplace environment and long-term maintenance capabilities. High-quality lifting equipment pays for itself through reliable performance and reduced downtime costs.

Take time to properly assess your application requirements before making your final choice. The correct belt hoist system will improve your productivity and at the same time the safety of the operator and the durability of the equipment. Don’t let poor hoist selection compromise your lifting operations when better choices are readily available.